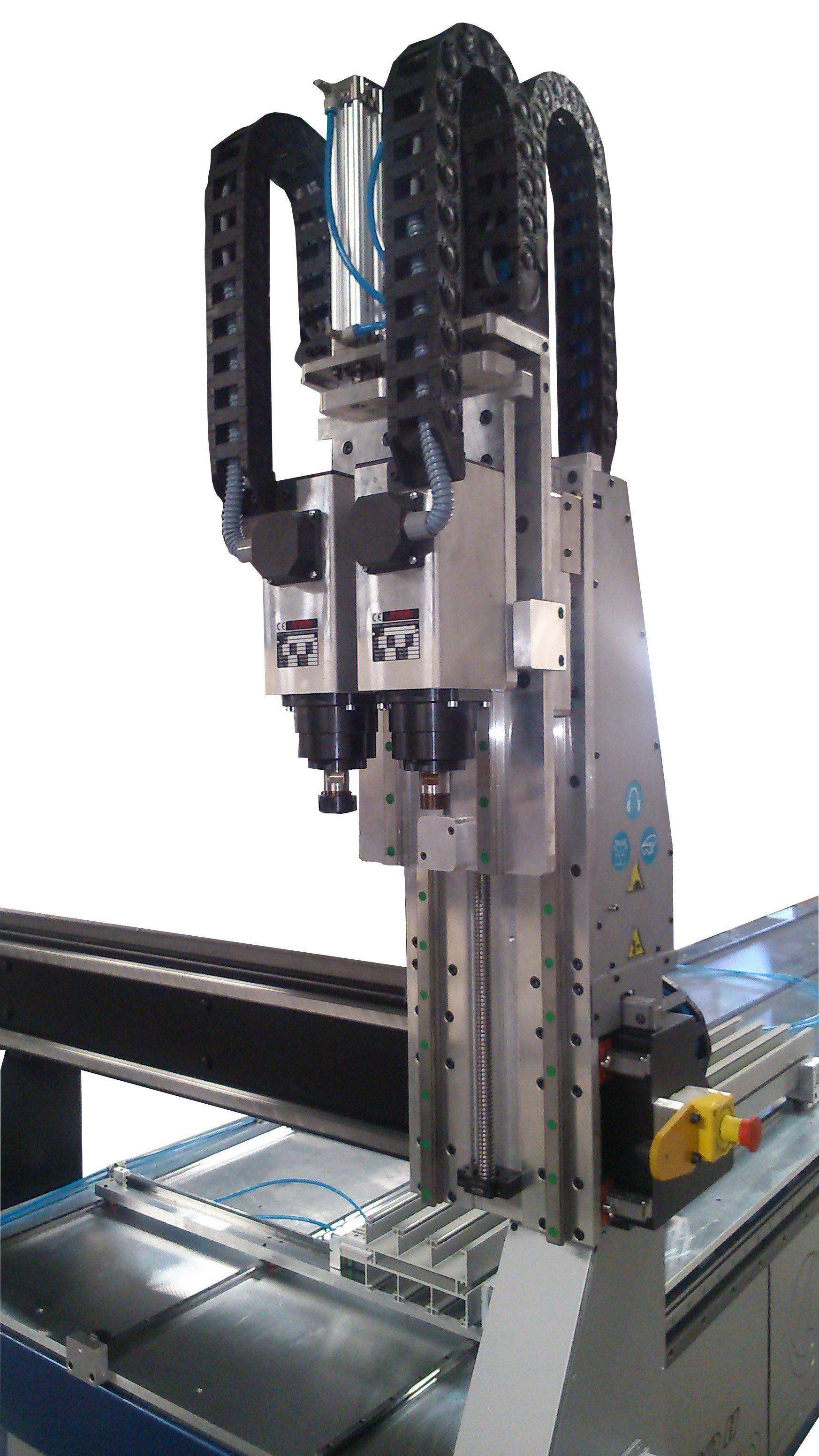

KSD 8010 PRO II

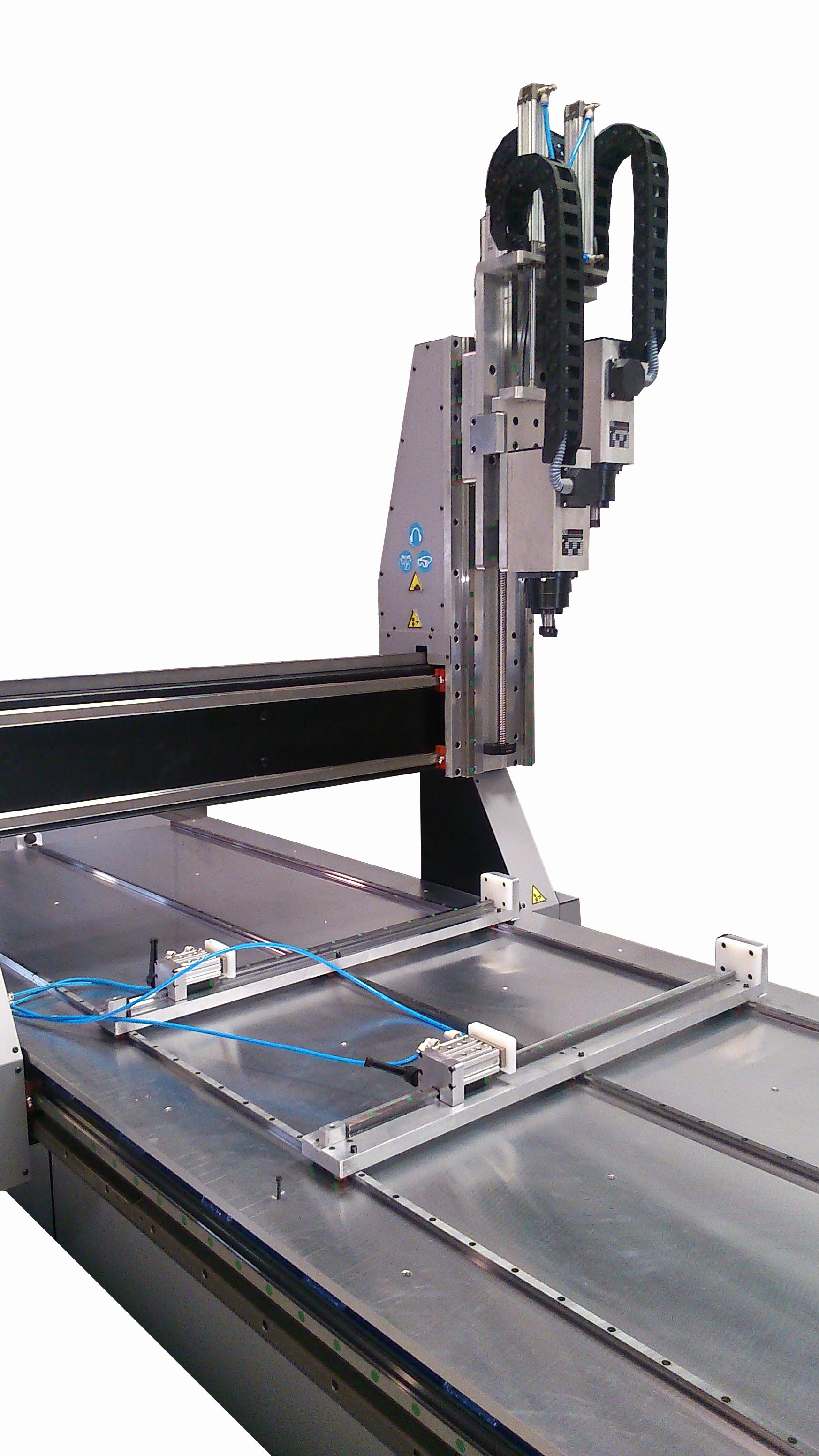

Machine KSD 8010 PRO II, is a milling machine of numerical control CNC, professional, of high performance, of three axes with bench (table of work) and mobile bridge with displacement on all the useful surface of work.

Machine KSD 8010 PRO II, is a milling machine of numerical control CNC, professional, of high performance, of three axes with bench (table of work) and mobile bridge with displacement on all the useful surface of work.

Is composed of:

• Monocoque chassis in CNC machined steel.

• Useful size: 8000x1000x200 mm.

• Bench formed by grooved aluminum plate on the entire working surface of 20 mm with grooves to house the fastening elements of the materials to be machined.

• X: 30 mm square guides. with 13 HGR30R linear bearings.

• Y: 25 mm square guides. with 2 linear bearings HGR25R.

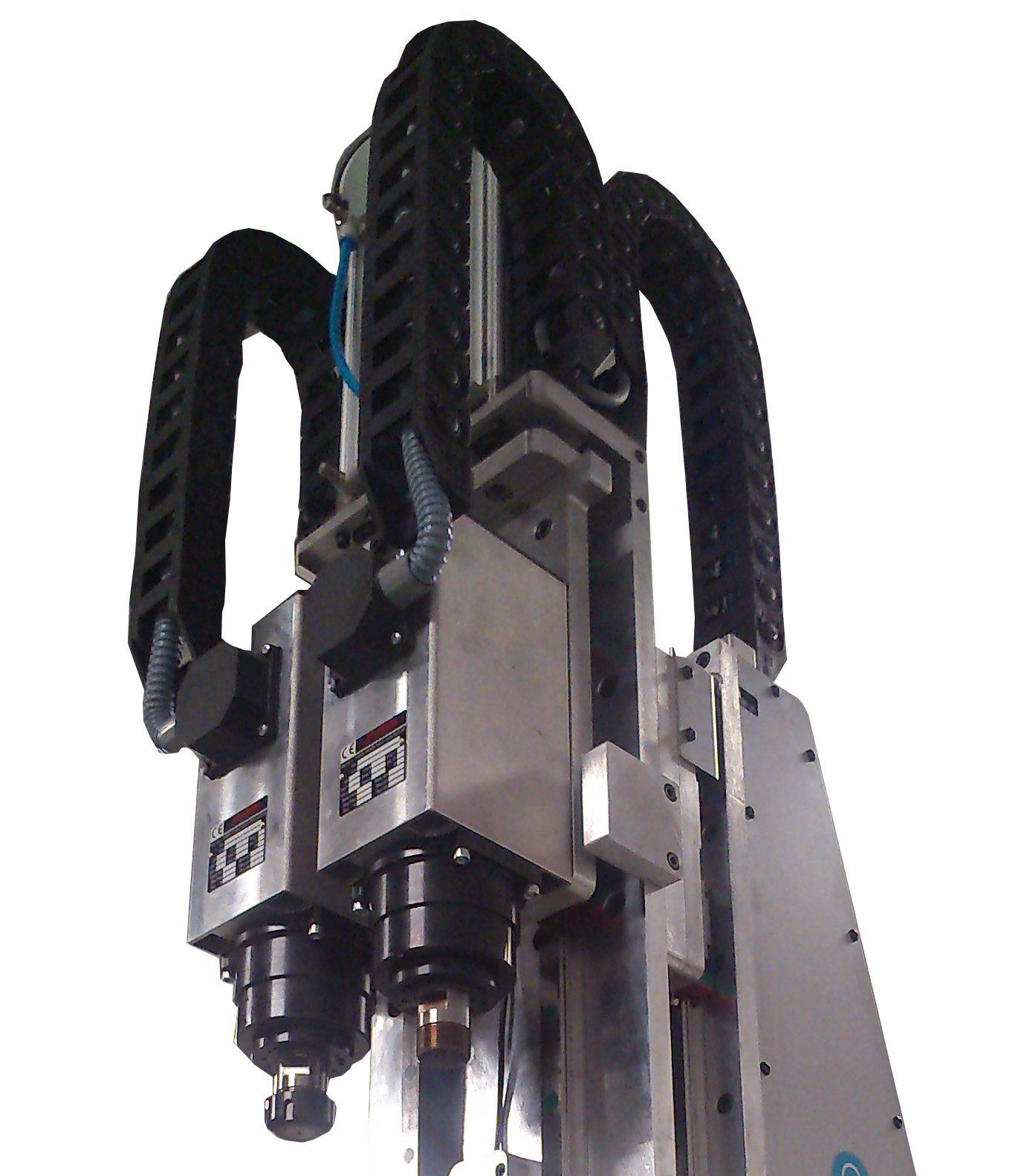

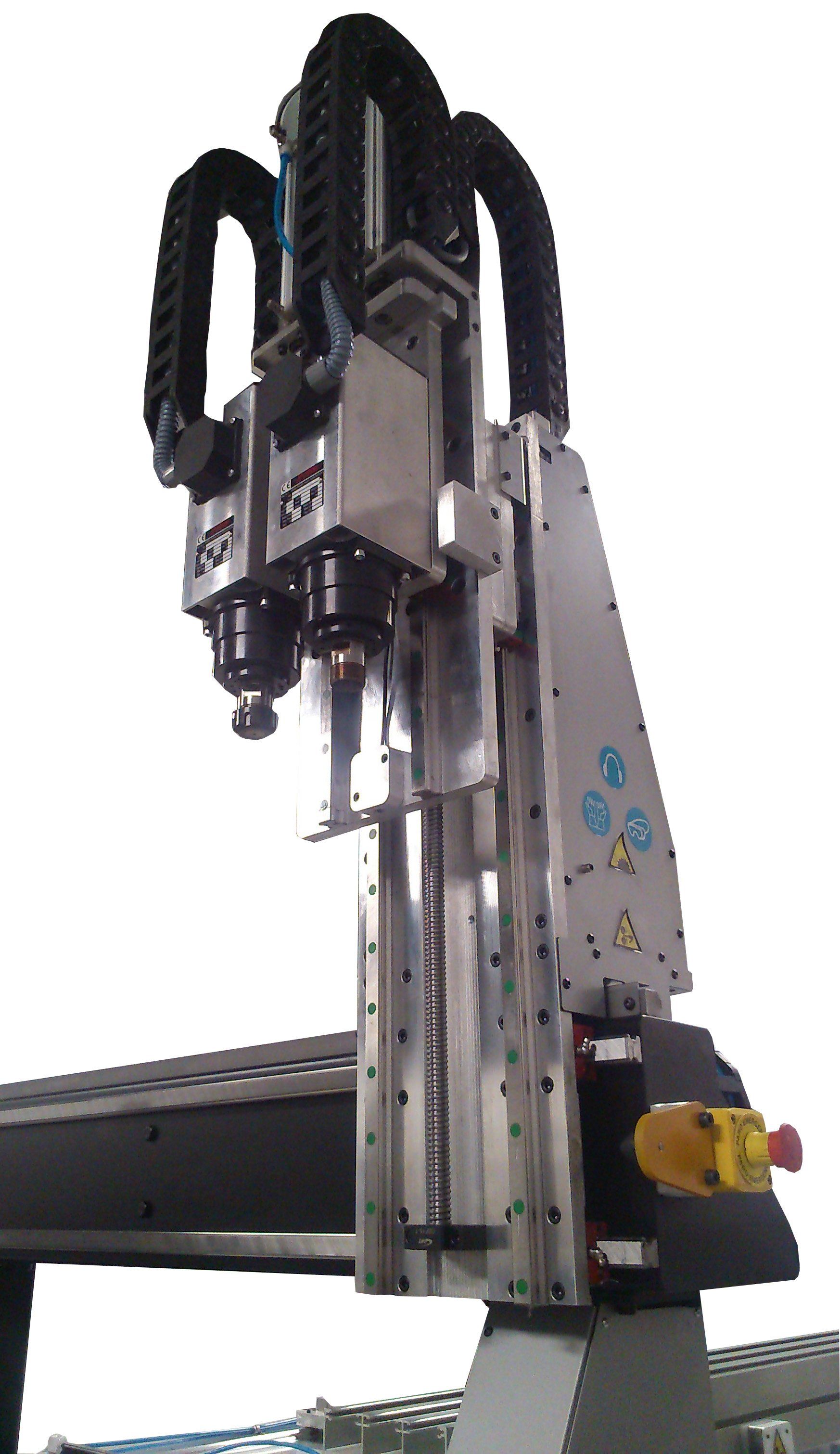

• Z: 25 mm square guides. with 10 linear bearings HGW25.

• X, Y: Rolled ball screw with 32 mm ball recirculation nut and BK / BF supports.

• X axis: Double direct drive engine to spindle, with 20 mm ball recirculation nut. (one in each guide)

• X1, X2: Panasonic A5-1,5 Kw-A1 engines

• Y axis: Direct drive engine to the spindle, with 20 mm ball recirculation nut.

• Y1: Panasonic A5-1,5 Kw-A1 engine

• Z axis: Double direct drive engine to the spindle, with 20 mm ball recirculation nut.

• Z1, Z2: Panasonic LIQI 1 Kw engines.

• 2 AC Digital Drivers. MCDJT3220.

• 3 AC Digital Drivers. MDDHT3420.

• 5 inductive positioning sensors.

• Encoder resolution engine 10,000 psi / rev.

• Electronic resolution of 0.025 mm machining.

• 3 Emergency stop points.

• Automatic calibration of the height of the tool.