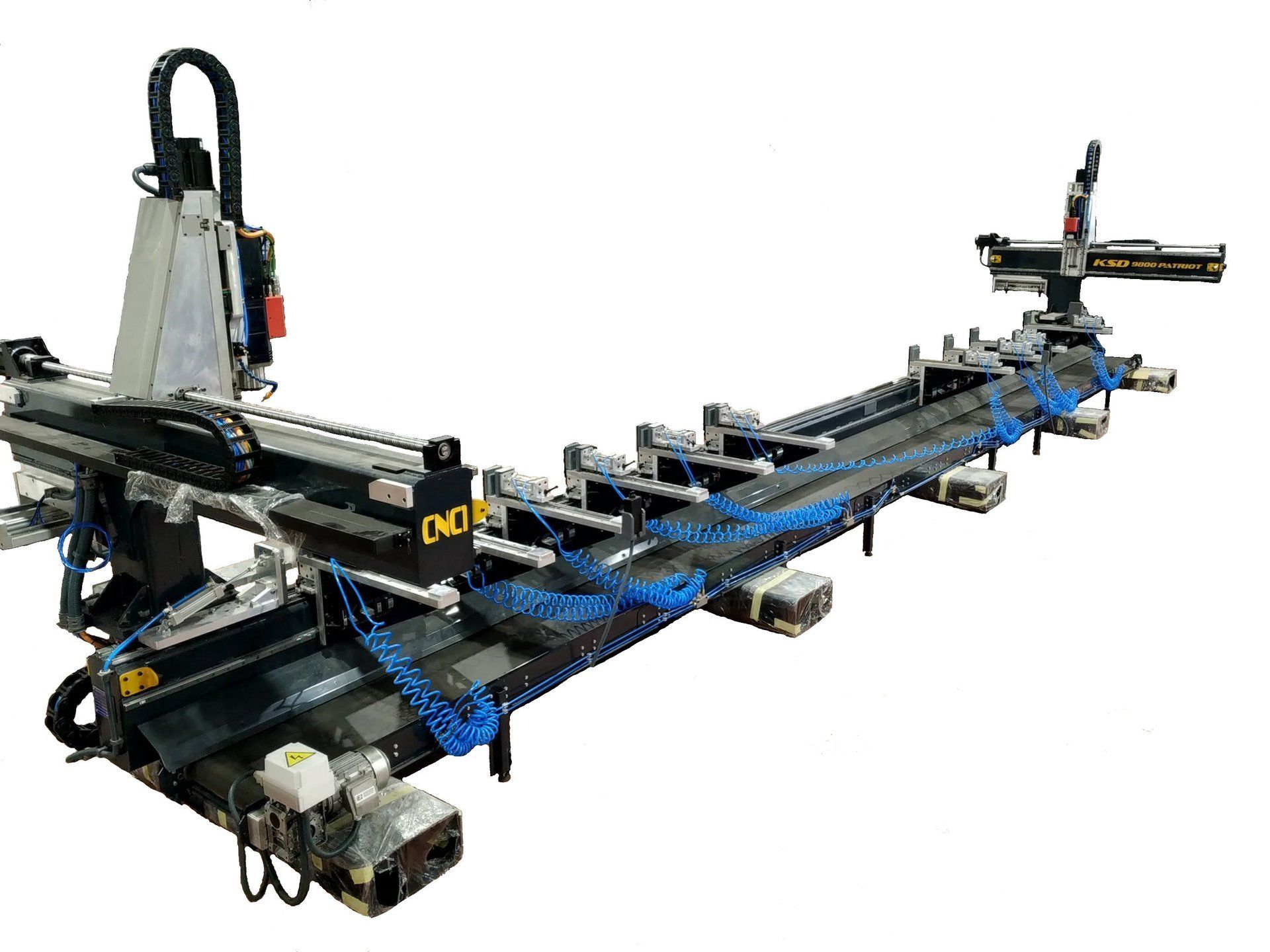

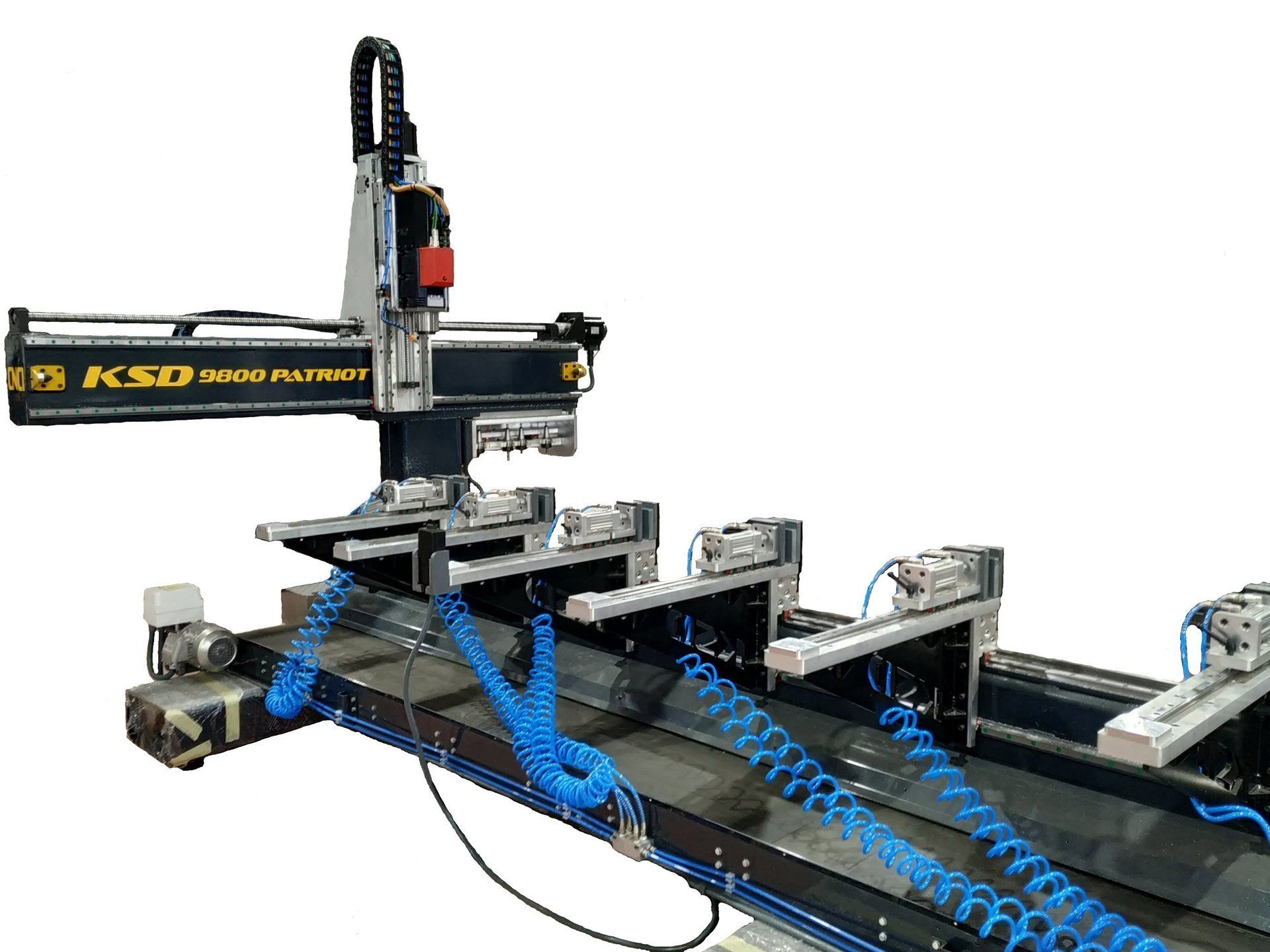

KSD 9800 PATRIOT

KSD 9800 2P PATRIOT, is a multithreaded CNC milling machine. Formed by a group of 3 axes (x, y, z) interpolated for the realization of high performance machining on profiles of non-ferrous materials. It has a set of 10 movable jaws in a manually way to support better the piece.

KSD 9800 2P PATRIOT, is a multithreaded CNC milling machine. Formed by a group of 3 axes (x, y, z) interpolated for the realization of high performance machining on profiles of non-ferrous materials. It has a set of 10 movable jaws in a manually way to support better the piece.

Is composed of:

• Monocoque chassis in CNC ground steel for the machining and cutting area.

• Chassis in folded sheet steel S235 with lacquered paint.

• Approximate useful size of the machining area: 9800x1000x300 mm.

• X1, X2: Transmission of the linear movement through rack-and-pinion of high precision.

• Y1, Y2: Rolled ball screw with 20 mm ball recirculation nut and BK / BF supports.

• Z1, Z2: Laminated ball screw with 20 mm ball recirculation nuts and BK / BF supports.

• Axle X1, X2: with built-in gearbox and direct transmission to the shaft.

• Y1 axis, Y2: with direct transmission to the spindle, with 20 mm ball recirculation nut.

• Z1, Z2 axis: with direct transmission to the spindle, with 20 mm ball recirculation nut.

• 2 milling engines AF11012-6 / 2 CU ISO 30 EV 8, 5 KW ELTE 8,5 Kw, with Mitsubishi variator of 11 Kw and variable speeds from 0 to 18,000 rpm. Tool holder by ER20 Clamp that allows a tool diameter of 1 to 12 mm.

• 4 Panasonic HME154G1G 1.5 Kw servomotors, located on X, Y axes

• 2 servomotors Panasonic MSME104C1H 1 Kw., Located on Z axis

• 6 Panasonic MDDHT3420BA1 1.5 Kw drivers.

• 6 inductive positioning sensors.

• Robotic special screened cabling.

• Built-in ABB safety relay for emergency stop system connections.

• Special security enclosure by metal fencing with emergency stop of the machine.

• Encoder resolution engines 10,000 psi / rev.

• Electronic resolution of 0.025 mm machining.

• Desktop computer + control area attached to the machine.

• Control Software "KSD ISOUS" 2.0 (G-Code Iso, PLT, DXF).

• Hardware Control NGWARP + 3xNGIO

• Communication via Ethernet cat. 5.

• Visualization and execution of work by screen, estimation of remaining time and the possibility of executing automated movements.

• Origin Relative work points in the programmable XYZ axes.

• Matrix programming machining at the foot of the machine.

• Start of the program at any point of the machining.

• Execution Change of speed and revolutions of the milling engines in real time.

• 4 emergency stop points.

• Manual / automatic calibration of the height of the tool.

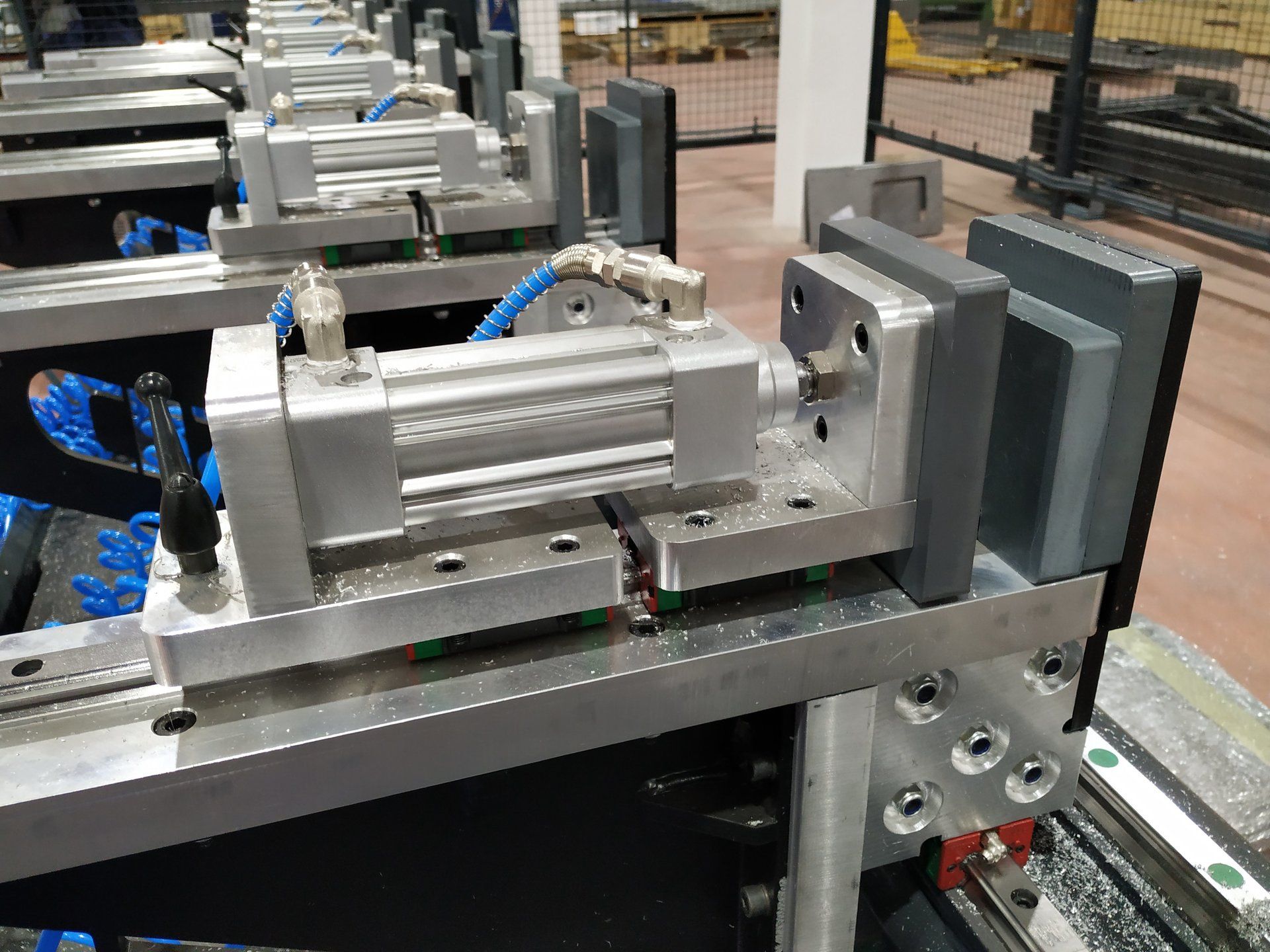

• 10 movable jaws adaptable manually for a better grip of the piece.

• 2 air / coolant diffusers.

• 10 electrovalves for the realization of pneumatic actuators.

• 4 mechanical limit switches for safety

• Conveyor belt with folded sheet.

• 1 engine reducer for conveyor belt SITI MU-63 R-1/40 1 CV 1500 b-4

• 2 infrared security barriers Panasonic Security SF4B-C

• Start / stop pushbuttons, located outside the work area

• Hand Wheel for CNC manual control.

• Automatic jaw activation.