KSD AIRCUT

The AIRCUT 600 machine is a high-precision knife cutting unit with numerical CNC control of three axes with lateral movement of the cutting unit. It is intended for cutting plastic materials in bars or slats.

The AIRCUT 600 machine is a high-precision knife cutting unit with numerical CNC control of three axes with lateral movement of the cutting unit. It is intended for cutting plastic materials in bars or slats.

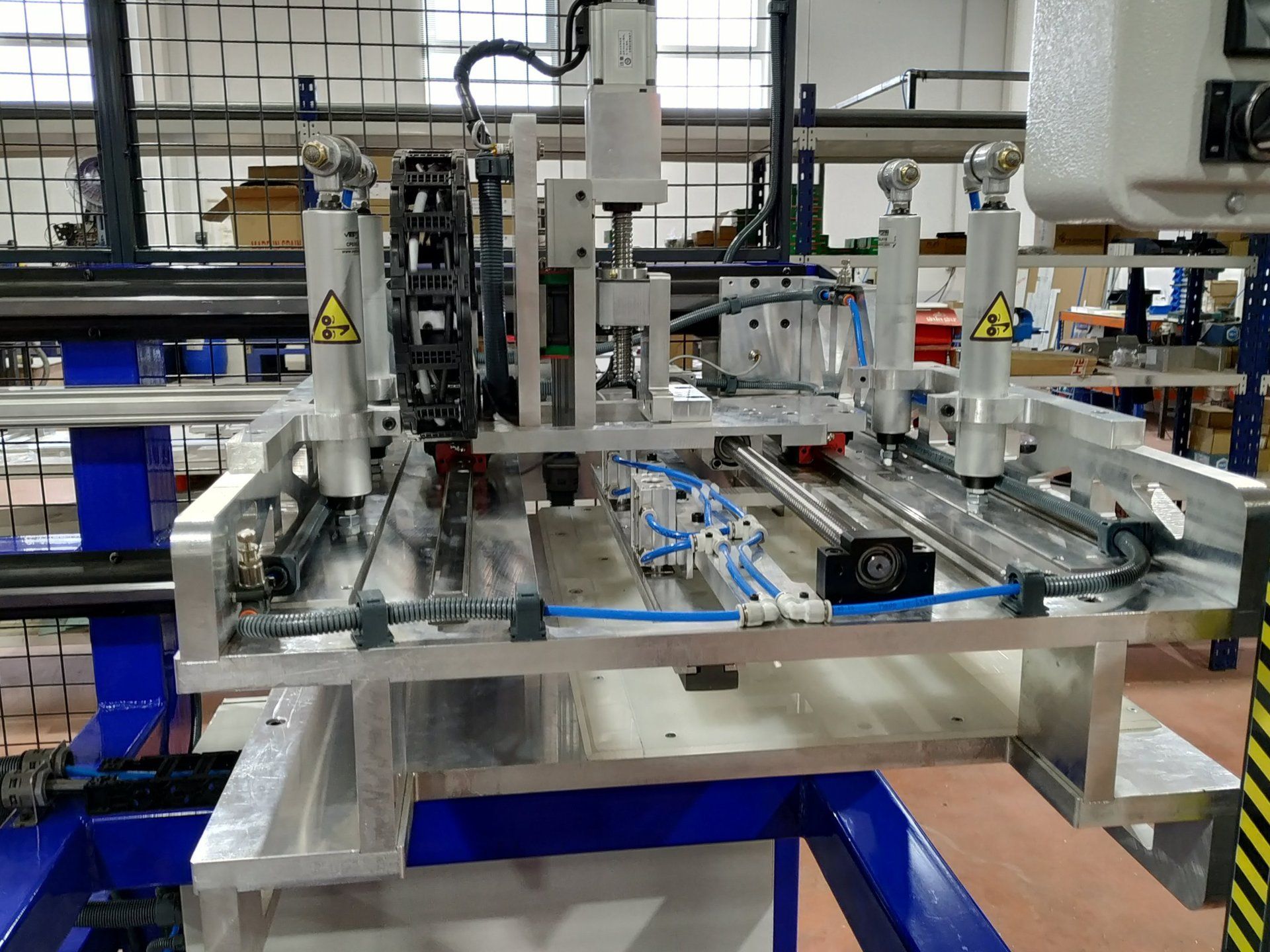

Is composed of:

• Monocoque chassis made of steel with folded insert to accommodate the guides.

• Useful size of the work area: 1300x620x80 mm.

• 25 mm square guides with 7 linear HGW25 bearings.

• Z axis: 20 mm spindle with ball recirculation nut.

• Y axis: 20 mm spindle with ball recirculation nut.

• X axis: Movement through pneumatic transmission (see Annex I).

• Y axis: Panasonic AC220 servo engine with direct transmission to the spindle, with 20 mm ball recirculation nut.

• Z axis: AC220 Panasonic servomotor with direct transmission to the spindle, with 20 mm ball recirculation nut.

• 4 cylinders ISO 6432 Ø 25x100 mm magnetic

• 1 cylinder without stem CN.

• 2 Panasonic AC220 Servomotors.

• 2 Panasonic AC220 Drivers.

• 4 inductive positioning sensors.

• Engine Encoder Resolution: 10000 psi / rev.

• Electronic resolution of 0.025 mm machining.

• System of lateral displacement and guide of slats.

• High performance work surface (see Annex I).

• Milling or cutting unit (see Annex I).

• Positioning motors of the cutting unit on Y, Z axes (see Annex I).

• Protection, by means of protective hood of the cutting unit.

• Automatic calibration of the height of the tool.

• 1 emergency stop point that allows automatic locking of the machine in case of opening of the protective hood during operation.