KSD PLOTTER 3250

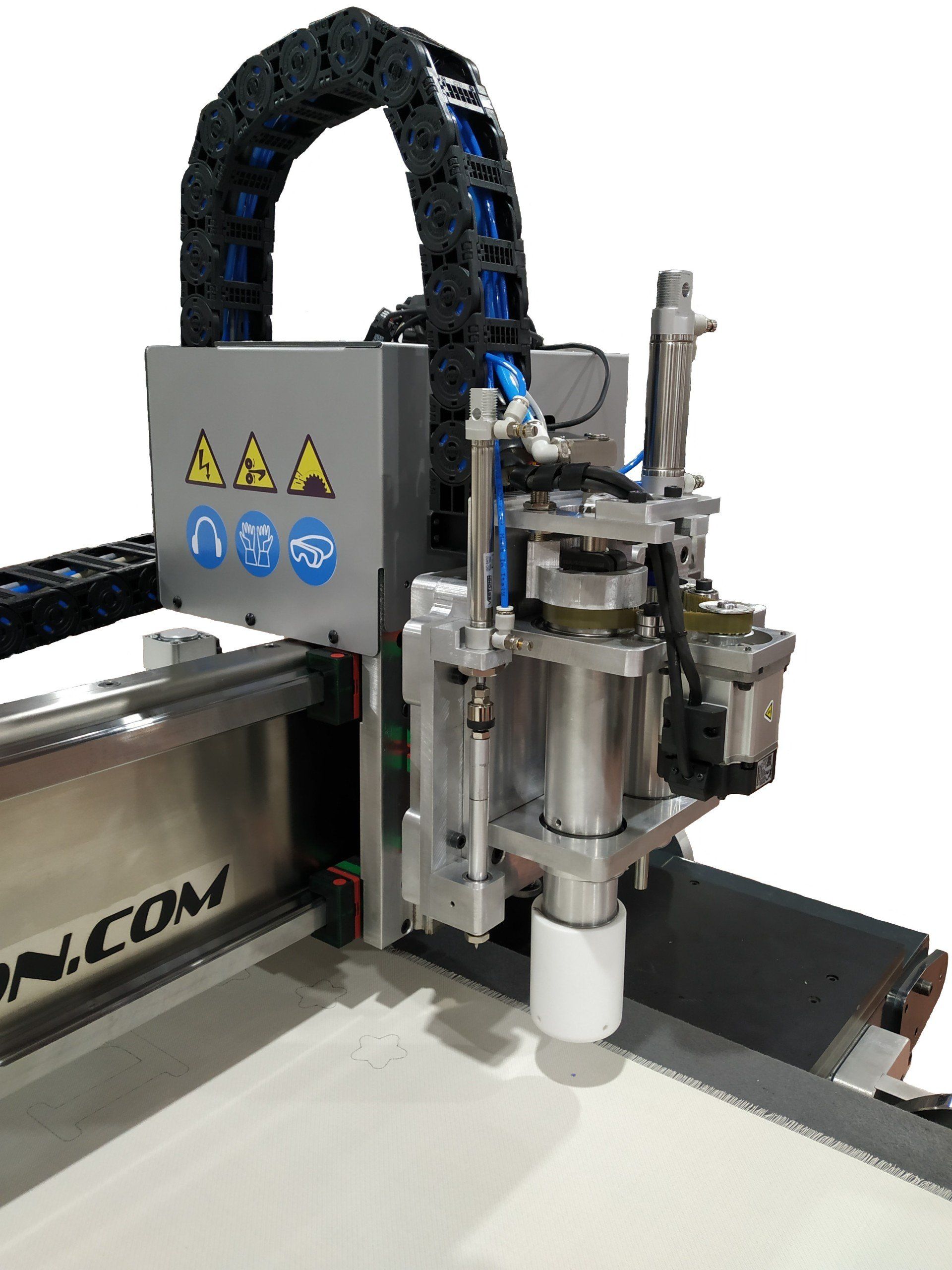

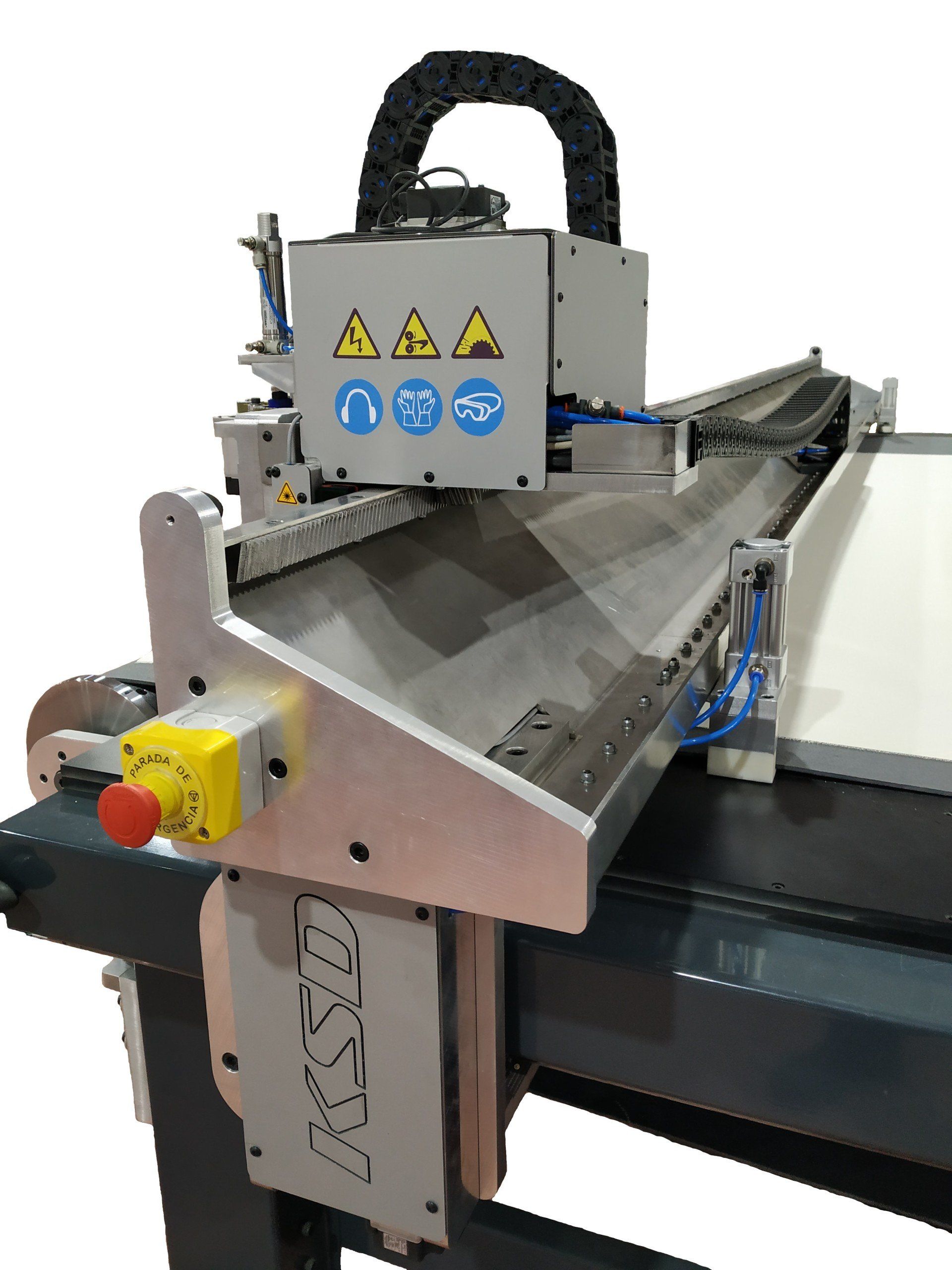

The model of machine KSD PLOTTER 3250, is a plotter of tangential cut, of numerical control CNC, professional, of high performance, of three axes with bancada (work table) and mobile bridge with displacement on all the useful surface of work, where 2 engines are housed, with 3 tangential cutting tools, laser pointer and marker pen. It is equipped with a vacuum system on the entire work surface.

The model of machine KSD PLOTTER 3250, is a plotter of tangential cut, of numerical control CNC, professional, of high performance, of three axes with bancada (work table) and mobile bridge with displacement on all the useful surface of work, where 2 engines are housed, with 3 tangential cutting tools, laser pointer and marker pen. It is equipped with a vacuum system on the entire work surface.

Is composed of:

• Chassis mounted in folded sheet 4 mm thick.

• Useful size: 3200x5000x100 mm.

• Vacuum table composed of a double system of TRESPA high density phenolic panels of 12.7 mm. Double perforated system.

• 2 Airtech vacuum pumps ASC0415-1MT301-6, 3 Kw 380 vAC single stage, -220 mbar, 415 m³ / hour.

• Safety valve for excess vacuum.

• XYZ: Square guides of 20 mm and 25 mm, with linear bearings HGW25CC, HGH25CA, HGH20CAZ0H.

• X axis: Panasonic MSMD102J1S double motor (one in each guide) with precision planetary gearbox, helical rack and hardened and ground pinion.

• Y-axis: Panasonic MSMD102J1S engine with precision planetary gearbox, helical rack and hardened and ground pinion.

• Z-axis: Direct drive motor to the spindle, Panasonic MSMD102J1S with 20 mm ball recirculation nut.

• 2 motors for tangential cutting tool, Panasonic MSMD022J1S

• 4 AC Digital Drivers. MCDJT3220.

• 2 AC Digital Drivers. MBDJT2207.

• 6 inductive positioning sensors.

• Motors Encoder resolution 10,000 psi / rev.

• Electronic resolution of 0.025 mm machining.

• Dedicated computer.

• CNC control KSD 4.03.29 (G-Code Iso, PLT, DXF).

• Communication via Ethernet cat. 5.

• On-screen job display and remaining time estimation.

• Start of the program at any point of the machining.

• 3 Emergency stop points.

• Automatic calibration of the height of the tool.

• Panasonic photoelectric barrier.

• Conveyor belt