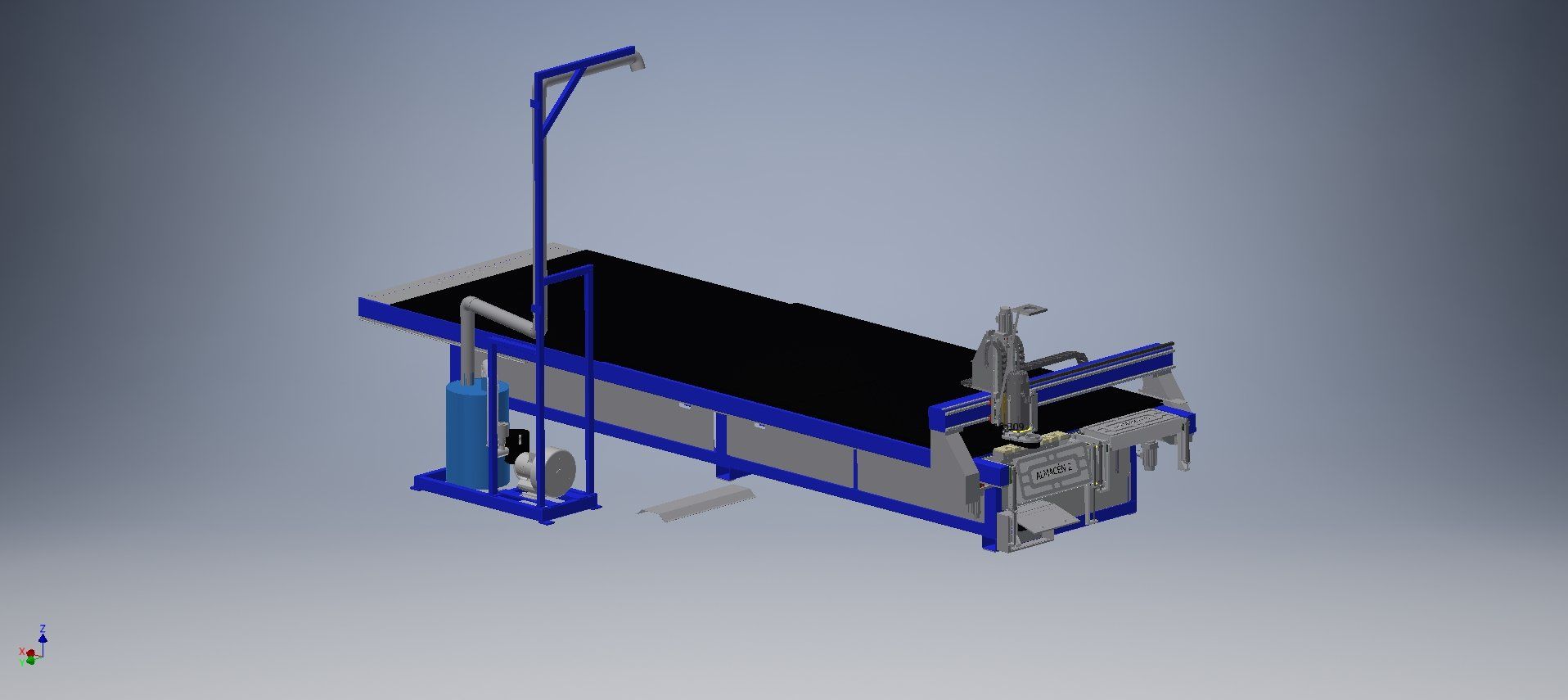

KSD 2161

Machine KSD PRO II 2161 3H, is a milling machine of numerical control CNC, professional, of high performance, of three axes with surface (table of work) and mobile bridge with displacement on all the useful surface of work, where lodge the three milling engines. It is equipped with a professional vacuum system on the entire work surface, pneumatic positioning system with retractable stops on the work surface and individual chip extraction system for each pre-installed milling engine.

Is composed of:

• Monocoque chassis in CNC machined steel.

• Useful size: 2150x6300x200 mm.

• Vacuum table composed of: rectified 5083 aluminum plate of 10 mm, PVC plate of 20 mm and DM 4 mm. Double perforated system.

• 2 vacuum pumps of 7.5 Kw 380 vAC, double stage, -400 mbar, 500 m³ / hour.

• Safety valve for excess vacuum.

• 6 independent vacuum zones.

• Pneumatic positioners.

• Pre-installed chip aspiration system.

• XYZ: Square guides of 25 mm with 12 linear bearings HGW25.

• Z: Rolled ball screw with 20 mm ball recirculation nut and BK / BF supports.

• X axis: Double engine (one in each guide) Gantry system with precision planetary gearbox, helical rack and hardened and ground pinion.

• Y axis: Engine with precision planetary gearbox, helical rack and hardened and ground pinion.

• Z axis: Direct drive engine to the spindle, with 20 mm ball recirculation nut.

• 3.3kw TeknoMotor AF milling engine, with 3.7 Kw Mitsubishi inverter and variable speeds from 0 to 18,000 rpm. Tool holder by ER25 Clamp that allows a tool diameter of 1 to 16 mm.

• 4 Hybrid engines with Encoder.

• 4 AC Digital Drivers.

• 4 inductive positioning sensors.

• Encoder resolution engines 10,000 psi / rev.

• Electronic resolution of 0.025 mm machining.

• Dedicated laptop.

• CNC control KSD 02.27 (G-Code Iso, PLT, DXF).

• Communication via Ethernet cat. 5.

• Wireless control for start control, pause, stop, execution speed, calibration of the Z axis and movements on XYZ axes.

• On-screen job display and remaining time estimation.

• 9 points on XY axes of programmable initial work.

• Matrix programming machining at the foot of the machine.

• Start of the program at any point of the machining.

• Change of speed of execution and revolutions of the milling engines in real time.

• 3 Emergency stop points.

• Automatic calibration of the height of the tool.