ALUMINUM PROFILES. METAL CARPENTRY

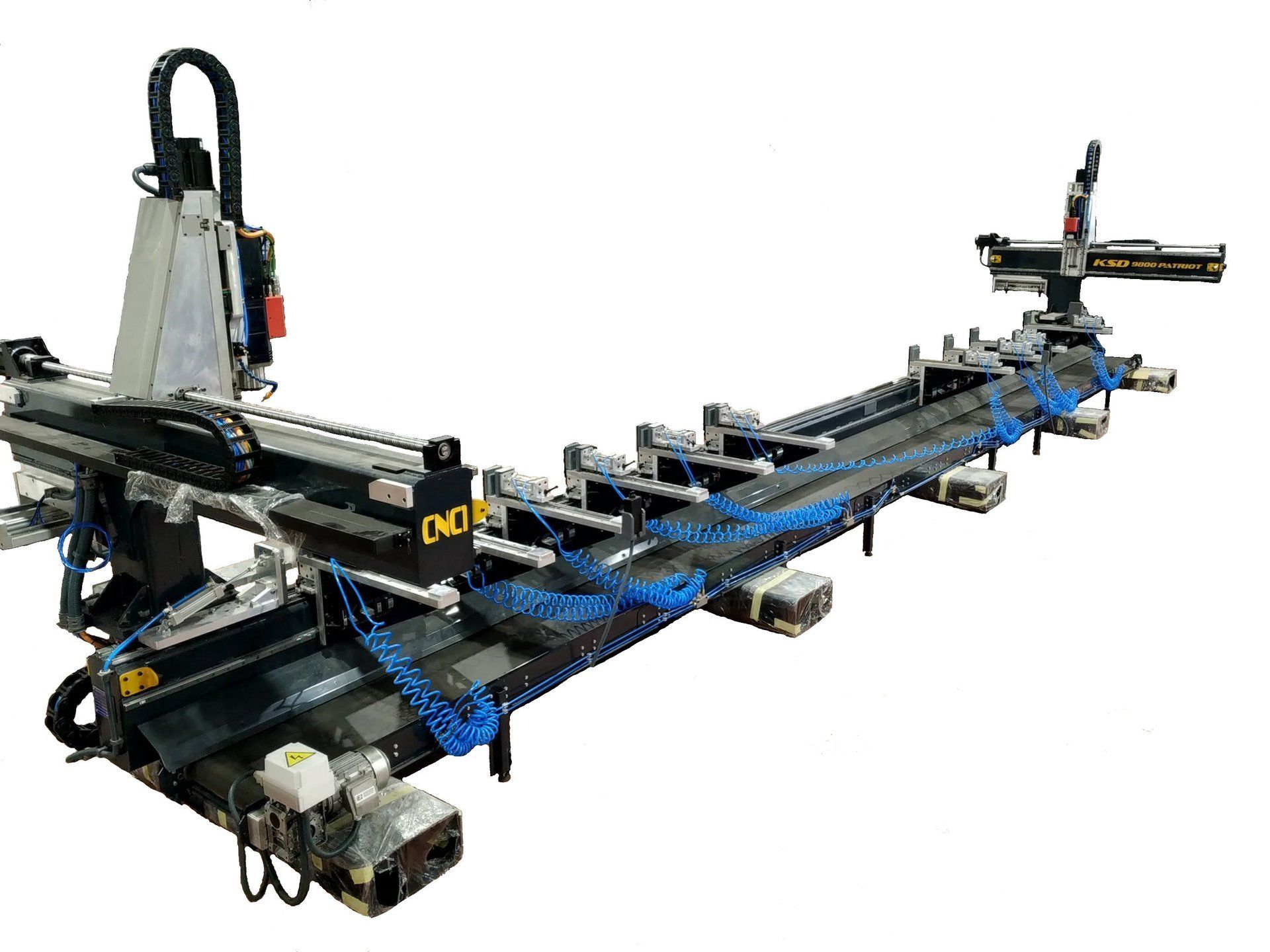

KSD 8010 PRO II

For its useful working dimensions, 1000x8000x300 mm, our milling machine allows the placement of aluminum profiles in lengths, without the need for handling, cutting or preconditioning.

This milling machine is designed and built in order to make work easier to work with this type of profiles, it incorporates a series of special features:

• A head with 2 2 Kw milling engines, with 2.2 Kw variable speed drive and variable speed of up to 18,000 rpm, which allows us to have 2 tools always available, allowing us to speed up the work by being able to perform two different jobs, on the same profile (for example, drilling and machining) without having to interrupt the work to change the tool.

• The bridge has a useful height of 300 mm to facilitate as far as possible the placement of large section profiles.

• The work table is, in its entirety, a rectified AW5083 aluminum plate of 10 mm.

• System for fixing pneumatic profiles. This system is divided into two zones, with triple guidance and with five differentiated and independent elements of fixation by means of high-performance pistons.

It is possible, in addition, the work with other multiple non-ferrous materials such as brass, copper, zinc, phenolic, agglomerates, DM, PVC, etc., because you have in your hands a Professional High Performance Milling Machine, designed, and manufactured to work

Other machines: